As noted, I had decided to use Peco Code 80 track, and already had a number of large insulfrog points.

I went back into Acorn Models where they had a box of Peco Code 80 flextrack, so I bought twelve pieces which would turn out to be be sufficient for all three sections. I set these out on the modules, and then tried various track arrangements. I also used my half-completed Dx as a prop to get a sense of the scale. It soon became obvious that the 450mm by 1200mm size of the sections offered plenty of scope in this scale. After a lot of thought I settled on the present arrangement.

The next challenge was the road bed. In the past I had used 5mm cork tiles, which were cut to fit with a craft knife and then glued down with PVA. On the join between modules I thought it necessary to have a firm surface under the track to avoid damage to the track at the edges, so intended to have a section of the roadbed made from mdf on either module edge.

A sudden brainwave led to the decision to have the whole roadbed cut from the 5mm mdf that was left over from the construction of the benchwork. This would be a whole lot simpler than the cork method. The disadvantages of this method were the potential sound problems which cork can help with, and also that unlike soft cork, it would not be easy to pin the track to the mdf surface. Given that I usually glue the track down, I decided that this last disadvantage was not a major problem, so I went with the mdf plan.

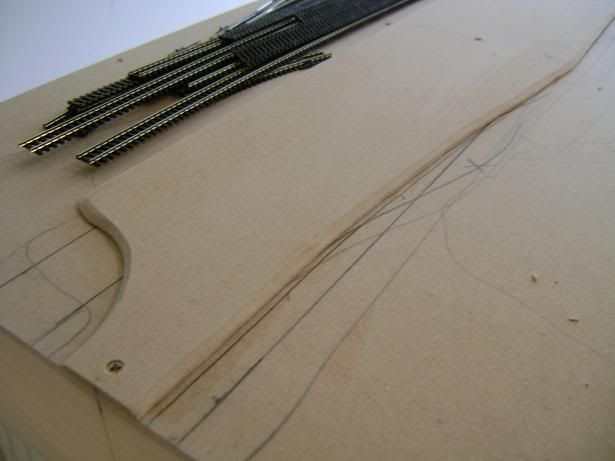

Getting out my cheap (and worryingly erratic) jigsaw, I cut the roadbed pieces to shape, including a section that would end up being the bridge. Then, using the sanding drum on my Dremel, I shaped the edges of the roadbed. I bought the Dremel to aid with cutting track, which it does awesomely; but it has ended up being hugely useful for all sorts of purposes. Best tool ever!

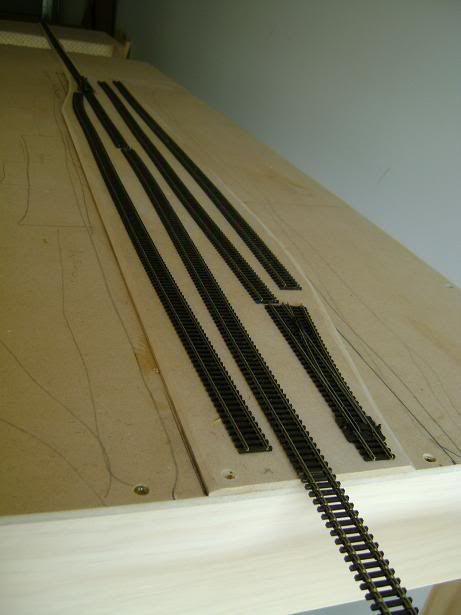

The roadbed sections were glued and screwed down, and then painted with a ground colour. This was sort of pointless, because the roadbed and track would eventually be airbrushed a dark brown anyway. I'm sort of picky and like to have things looking neat as I'm building them, even if it occasionally means putting in work that won't be scene in the finished product.

With this finished, it was time to start thinking about laying the track. This is where things stood for about a week. Everybody has bits of the hobby that they do not entirely enjoy, and for me this has usually been laying track, though I'm not sure why. Maybe it's because you have to be very methodical to get the track just right. Anyway, while I worked up my enthusiasm for laying the track I also had a chance to plan the wiring.

Next post: laying the track.

This is most enjoyable and enlightening to follow your progress. Thanks for writing it all up for us to read. Certainly gained some ideas for my own layout. It almost makes me want to start NZ120, but must finish my On30 layout first!

ReplyDeleteCheers!

ReplyDelete