I had used dressed timber and mdf on my previous layout with no hitches, and so having worked out the amount of material I would need for three 1200mm by 450mm modules, I headed down to the local Placemakers with a friend and his overly large trailer. I got around 5 metres each of 90mm planks, and 30mm by 40mm timber for the legs. I also picked up several sheets of 6mm mdf, screws, glue, and chicken wire. All this was eye-wincingly expensive, but it's nice to work with the right materials.

Back home, I sat and stared at the pile of wood for a couple of days. My woodworking skills are not the best, so I was a bit hesitant about starting. I also wanted to think through the construction sufficiently so to avoid mistakes along the way. You'll also note that I'm fortunate enough to have a clean, well-lit, and warm garage to build in, although it does get cold in winter.

I wasn't overly concerned with the weight of the modules, as I reckoned these will spend most of their time set up in the garage. I settled on a framing the modules with the 90mm timber, with a couple of cross braces. These were all screwed and glued together with minimal fuss, and to my surprise were mostly square!

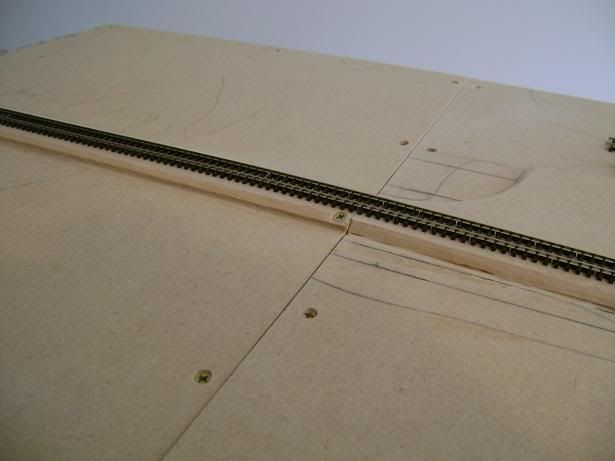

The mdf sheets I used are 1200mm long, so only the edge of a mdf sheet needed to be cut to get the correct size, and this was fixed to the top of the frame after pre-drilling all of the screw holes.

I finished off the three modules over the course of several evenings, and over all the process was a lot of fun. I'd like to get some power tools in the future for this kind of thing, because I used a handsaw throughout. A saw bench would be awesome!

The next challenge was attaching the legs, and I decided to use bolts and wingnuts, so it was back to the local Placemakers for these. The module standard designates a railhead height of 1200mm, which I think is ideal, though some people might find it a smidgen high. Before attaching the legs, I had wondered how stable the whole arrangement would be at this height, but after the legs were on it proved to be very stable. I looked around on the internet, and others have used a similar solution. Lots of hole drilling later, the modules were ready to assemble.

At this stage, the legs still need their adjustable feet, and I've purchased a couple of hundred (!) T-nuts for this purpose.

Here you can see how the legs are attached each with two bolts:

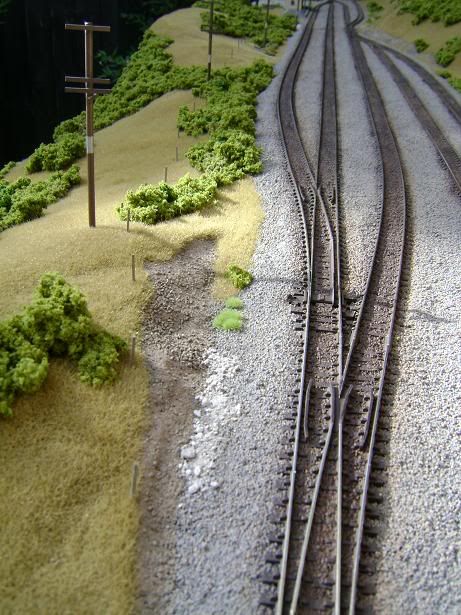

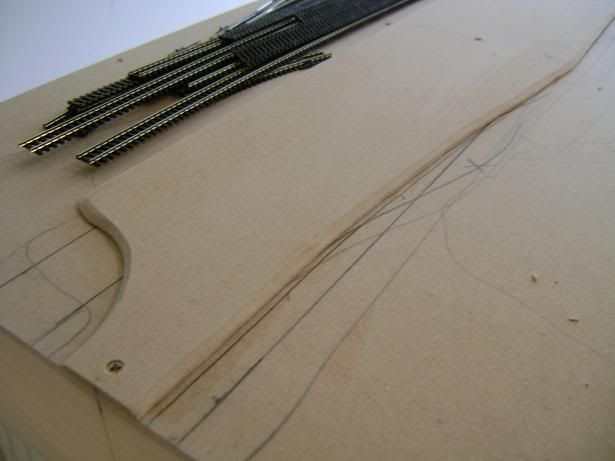

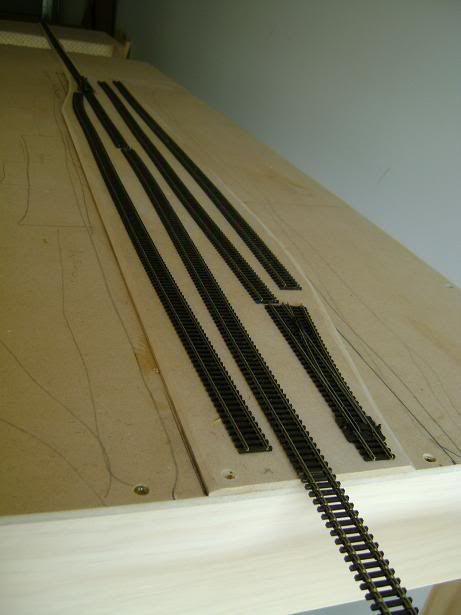

You will also note that two of the modules have cut out sections for the scenery. Lots of layouts I see have no depth beneath the railhead, with the track just plonked down on a flat piece of plywood. This often strikes me as really artificial, and would look especially so for the undulating countryside on New Zealand that I intended to model. So a little planning ahead was needed at this stage to envisage where the track was going to go, and how it would be situated in the landscape. One cut out was for a river I intended to build. Everyone loves a river!

Next post: planning the track layout and laying the roadbed.